Hello Houston! Are you ready to dive into the world of commercial refrigeration? Before you roll your eyes thinking it’s just another technical talk, hold your horses! 🤠 This one is about keeping your precious groceries from turning into an unintentional science experiment. We’re talking about nailing the high-pressure cut-out setting – a vital component for ensuring smooth operations in your refrigeration unit. Next time you sip that cold brew or enjoy chilled veggies, you’ll have a reason to smile knowing that your business is running like a well-oiled machine.

Unity Cooling Systems Inc., right here in the heart of Texas, prides itself on being the go-to guy for all your commercial refrigeration needs. We’ve partnered with industry giants such as Carrier and Turbo Air to ensure that you only get the best. In today’s post, we are demystifying high-pressure cut-out settings and why getting them right is as important as your morning coffee.

What is High Pressure Cut Out Control?

Let’s break it down y’all. The high pressure cut out control is like a referee in a tight football game making sure things don’t spiral out of control. In commercial refrigeration systems, this control shuts off the compressor when pressure exceeds safe limits. Why? Because no one wants a busted system leaking refrigerant or an unexpected sauna in their walk-in cooler.

This mighty component ensures smooth operation of your system without costly repairs and downtime. Think of it as a guardian angel for your system watching over every refrigerant cycle making sure everything is cool—literally and figuratively speaking. Without this little guy, pressure inside your unit could skyrocket causing damage to critical components and leading to serious meltdown (not emotional kind thankfully!).

Why Typical Setting for High Pressure Cut Out Matters

Now you may be wondering “why all this fuss over a setting?” Well partner, an improper setting is like cooking a brisket at too high a temperature – things can go south pretty fast. If the high pressure cut out setting is not dialed in correctly, expect equipment failures, refrigerant leaks or even complete system shutdowns. That’s more than just a hiccup; it’s a full-blown rodeo!

Getting this right ensures your refrigeration system hums along nicely, just like Willie Nelson in concert – smooth and reliable. By maintaining the typical setting you ensure peak efficiency, minimize risks and keep your energy bills from skyrocketing like Houston traffic during rush hour.

Understanding Refrigerants and EPA Regulations

Ah refrigerants – the lifeblood of any refrigeration system! But with great power comes great responsibility. The Environmental Protection Agency (EPA) has laid down the law to ensure we’re not just cooling our beer but also saving our planet. Compliance with EPA regulations is non-negotiable, especially for commercial setups.

Using the appropriate refrigerant type as per your equipment’s specs isn’t just a suggestion; it’s a mandate. Deviating from this can lead to heavy fines and, worse still, an inefficient system. Always make sure that your system uses the right stuff—like a good Texan uses mesquite for BBQ—it’s all about getting that perfect flavor (or in this case performance).

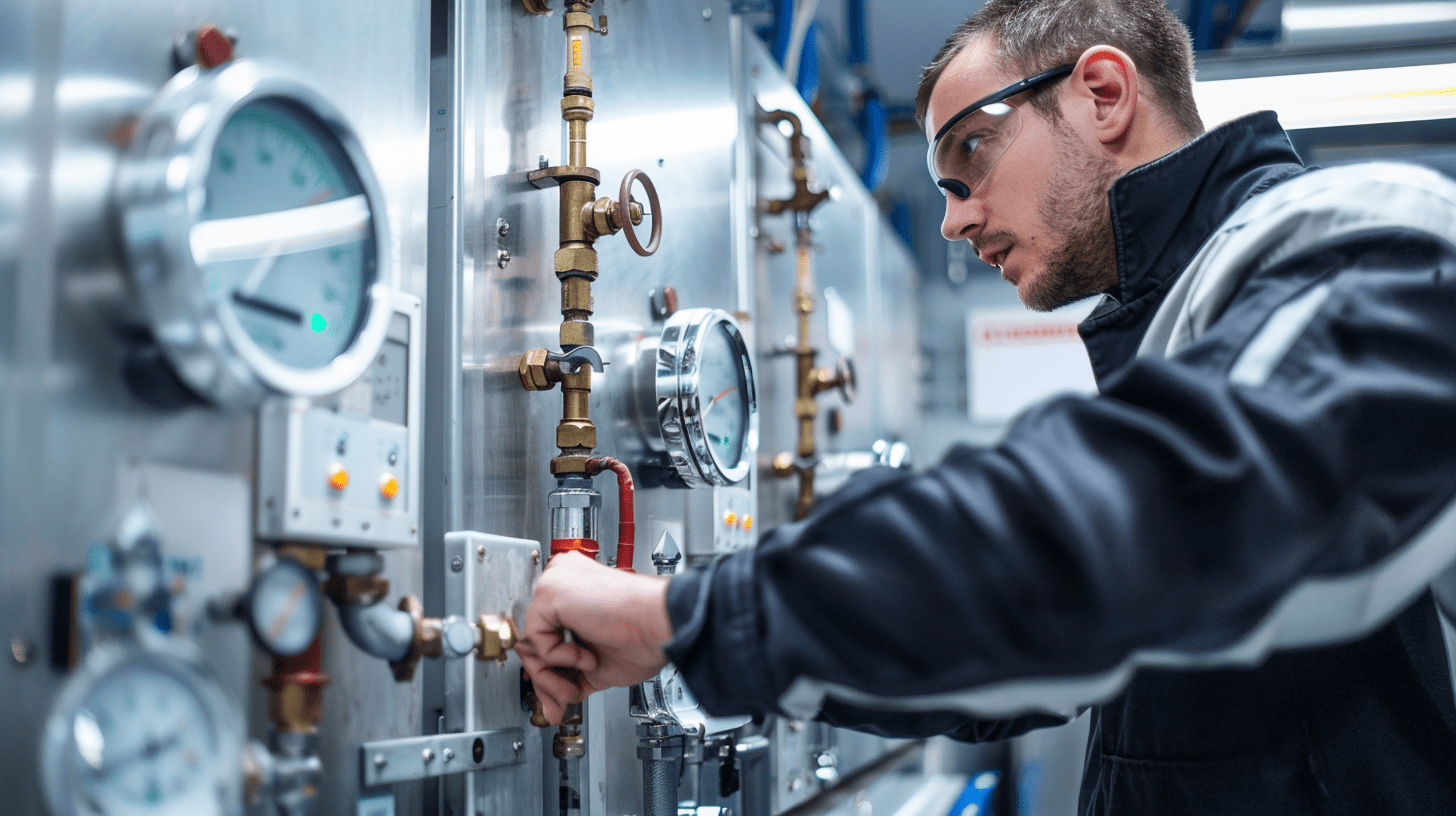

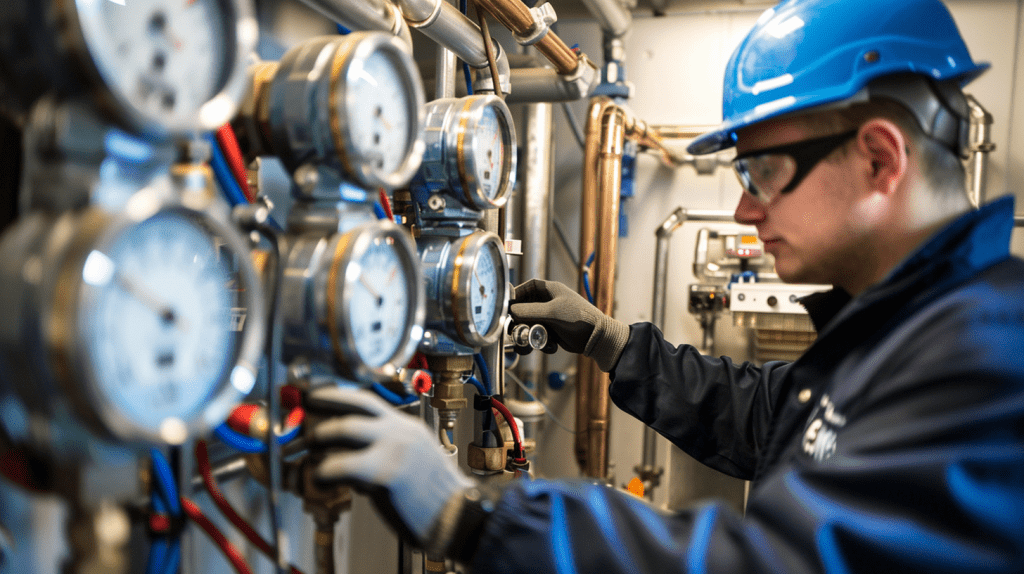

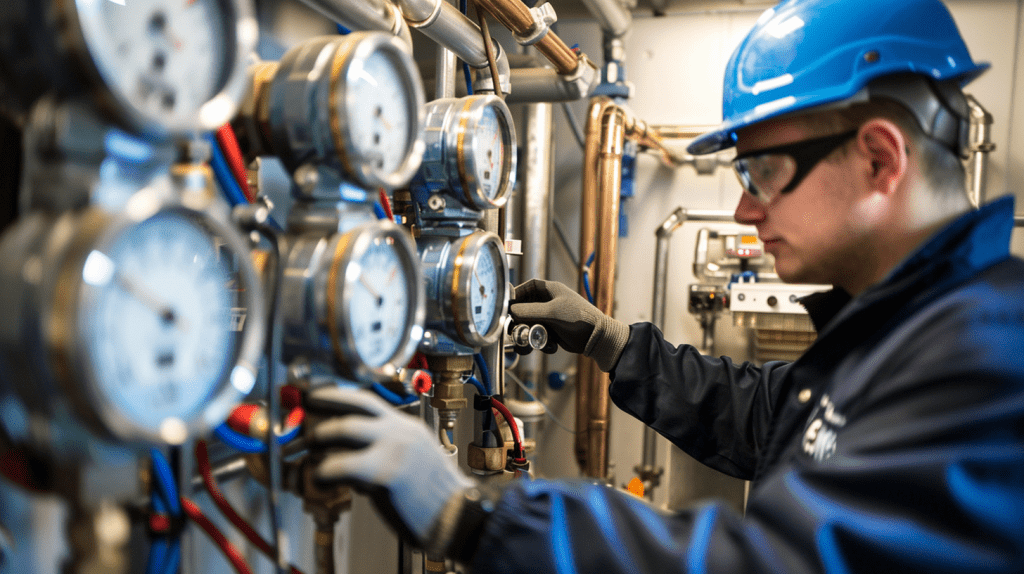

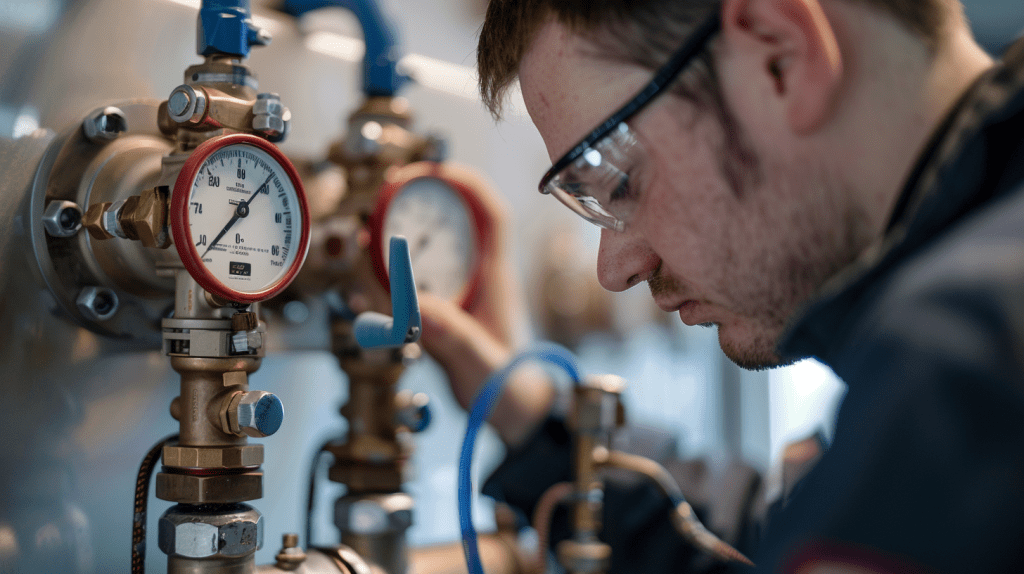

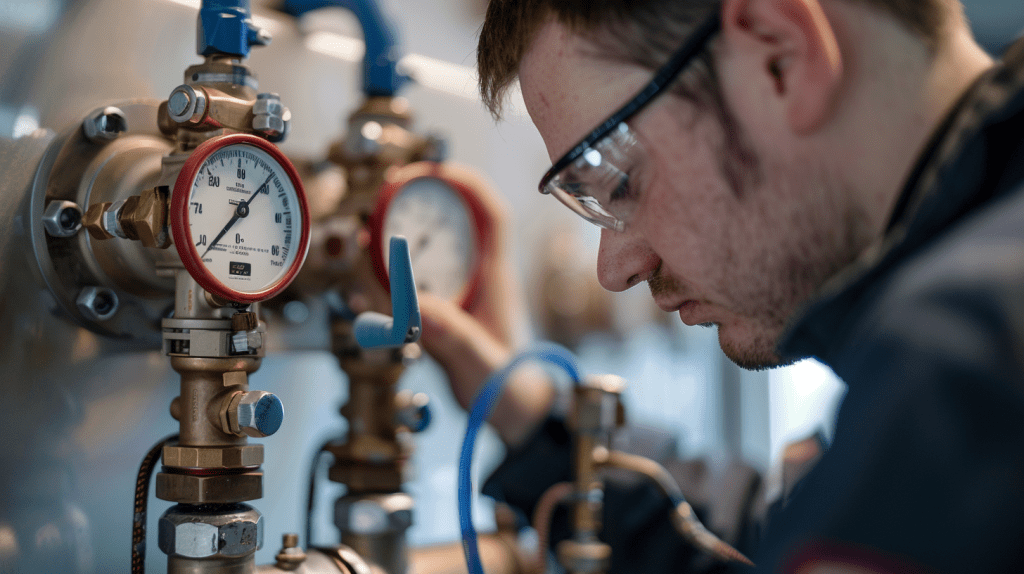

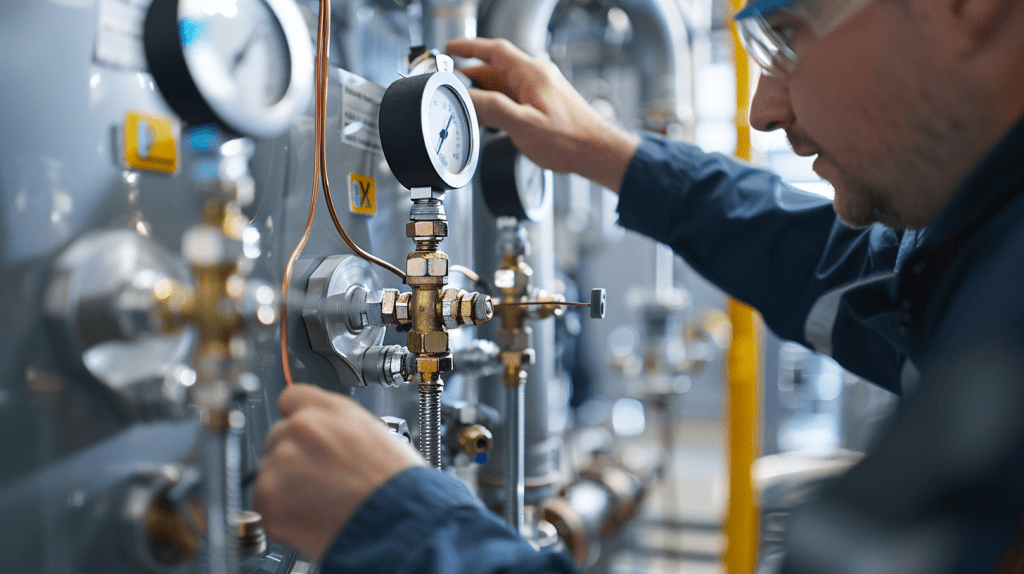

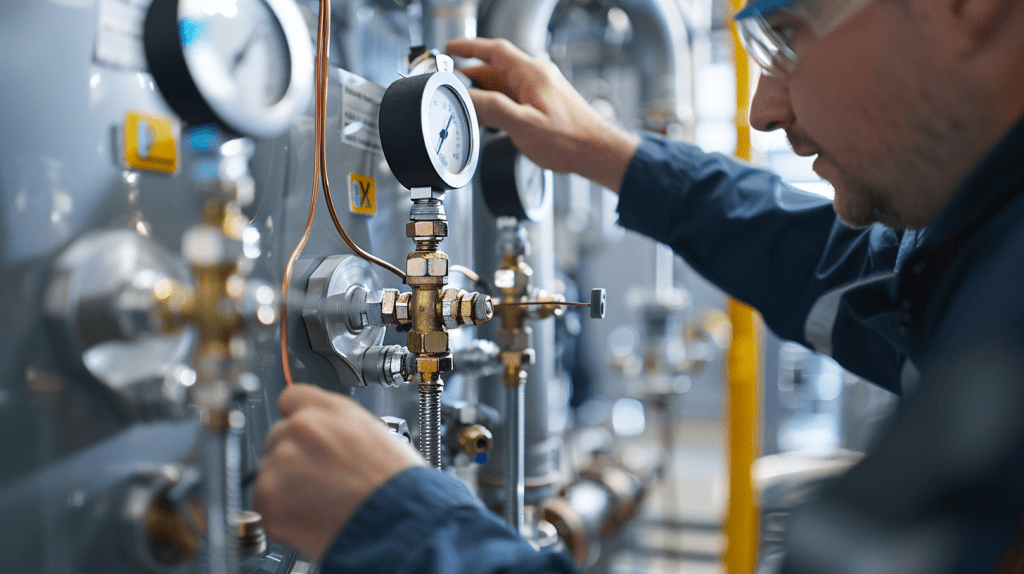

How to Verify and Set the High Pressure Cut Out

Ready to get hands-on? 🤔 Here’s how you can ensure your high-pressure cut-out is set to perfection:

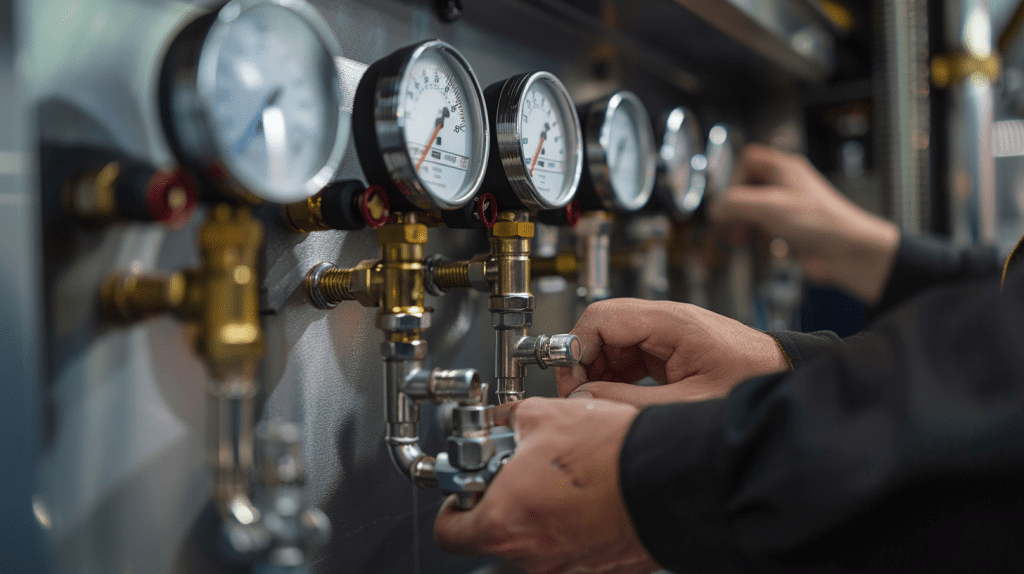

- Gather Your Equipment: Before you start, make sure you’ve got the right tools—handheld electrical testing meters, high-pressure manifolds, and adjustable wrenches.

- Set the Scene: Ensure your recovery unit used for evacuating the refrigerant is in place. Safety first!

- Verification & Adjustment:

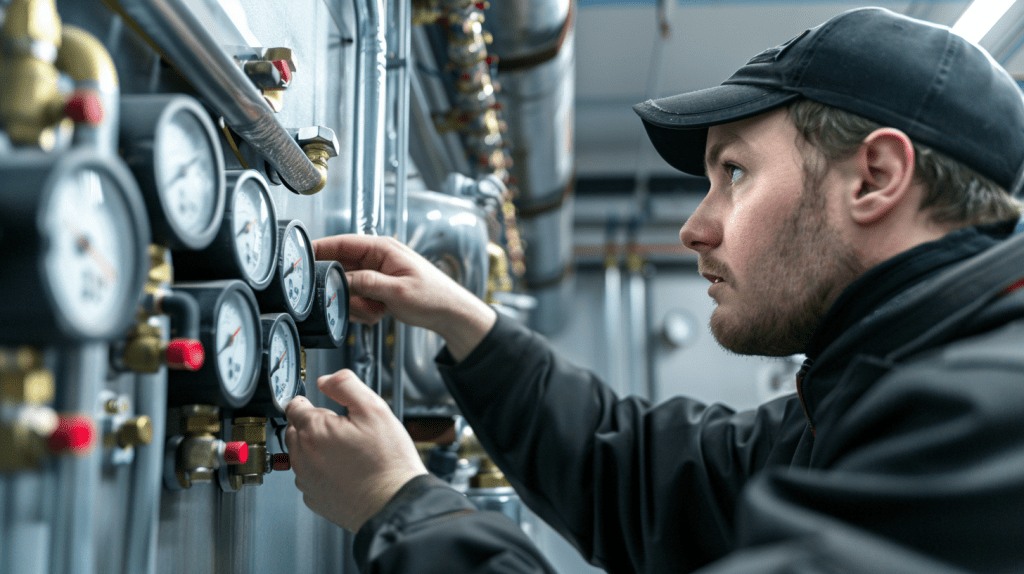

- Begin by checking the current setting using your electrical testing meter.

- Gradually adjust the setting to ensure your compressor operates within safe parameters.

- Run a few cycles to verify the setting and make further adjustments as needed.

Remember, it’s not just about setting it once and forgetting it. Regular maintenance ensures that your unit operates seamlessly, effortlessly cutting through tasks like a hot knife through butter.

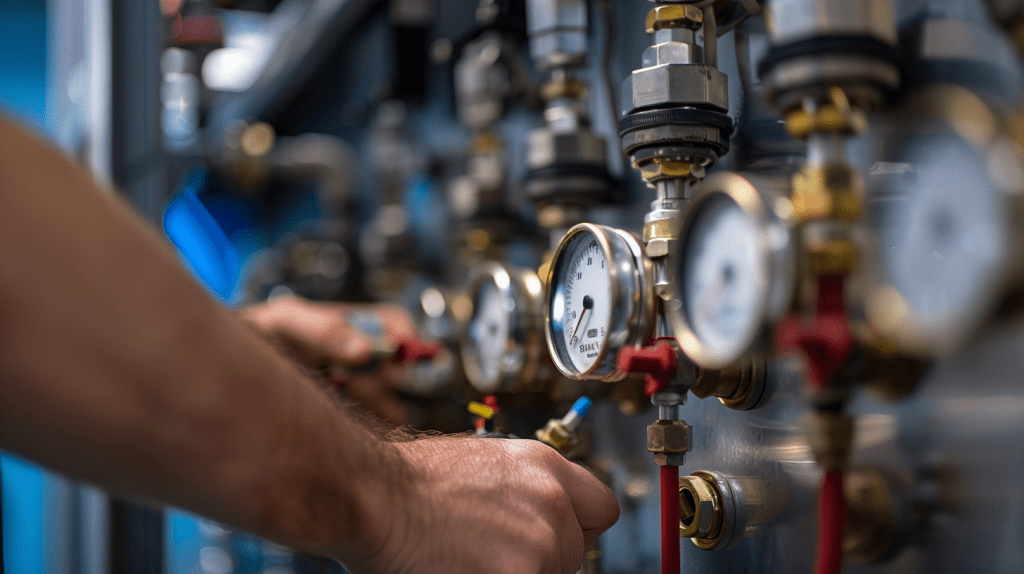

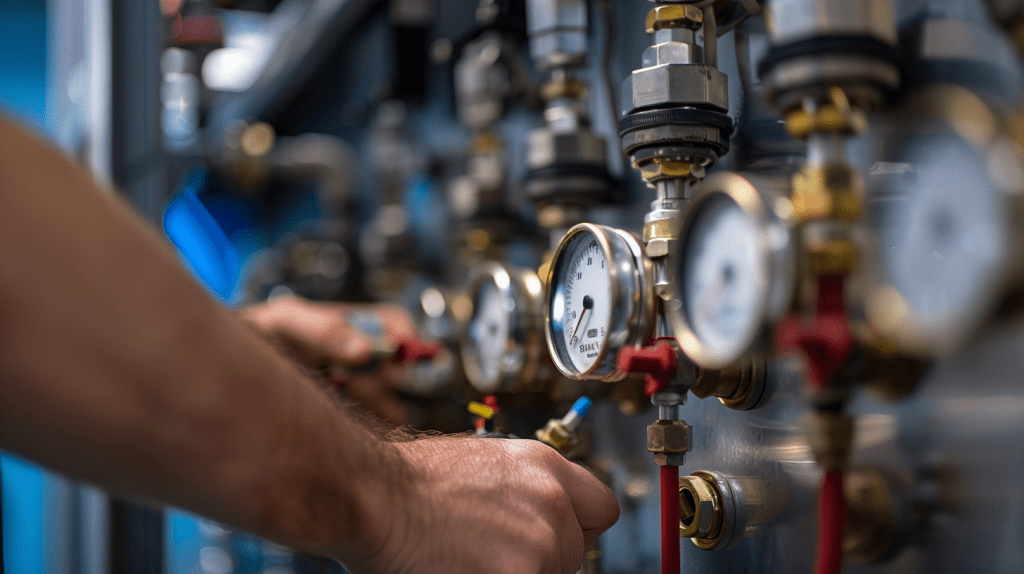

Equipment and Tools Needed

Alright, folks, let’s talk gear. For setting the high-pressure cut-out, you’ll need:

- Electrical Testing Meter: To measure the electrical load and ensure accurate settings.

- High-Pressure Manifold: Saves time and ensures accurate pressure readings.

- Adjustable Wrenches: Essential for making precise adjustments.

At Unity Cooling Systems Inc., we’ve got all the equipment you need to ensure your commercial refrigeration system operates efficiently. From recovery machines to state-of-the-art electrical meters, we’re your one-stop shop.

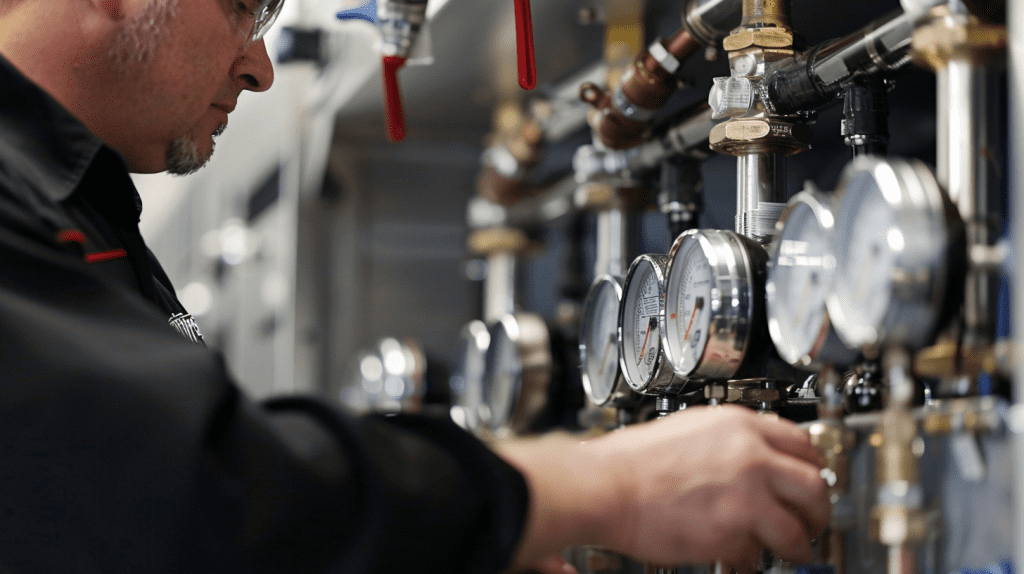

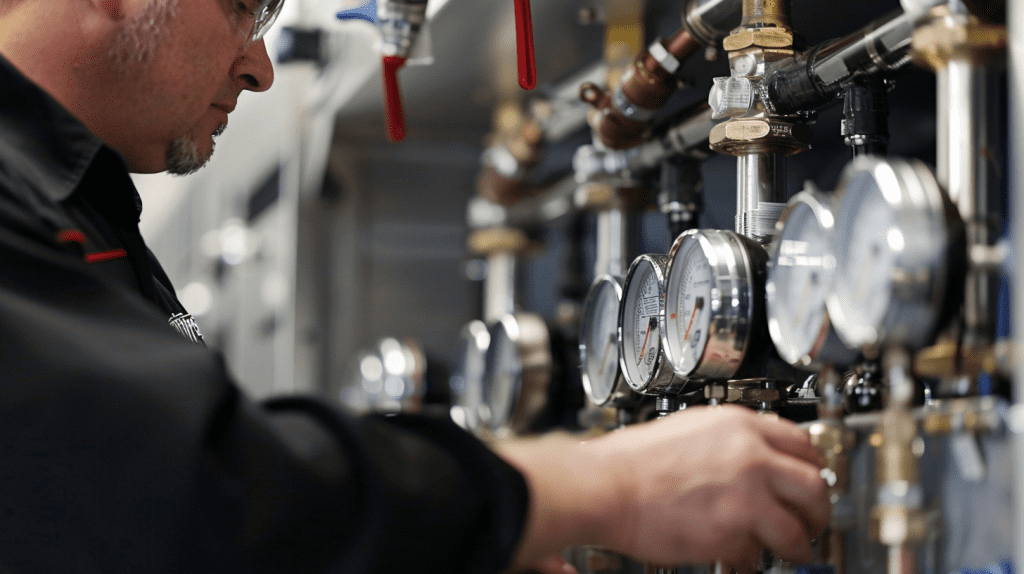

Best Practices for Setting the High Pressure Cut Out Control

It’s not all cowboy boots and honky-tonk! Setting the high-pressure cut-out control requires precision. Here are some tips:

- Know Your System: Each system has its quirks. Consider ambient temperature, compressor pressure, and condenser specifications.

- Stay Informed: EPA guidelines are your friend. Keep abreast of any changes to ensure compliance.

- Consistency is Key: Regularly check and adjust settings as needed. This ain’t a set-and-forget gig!

Your system’s efficiency and longevity greatly depend on these practices. Treat it well, and it’ll treat you better than Saturday night at the rodeo.

Common Issues and Troubleshooting

Even the best-laid plans can hit a snag. Here’re some common issues and how to troubleshoot them:

- Leaks: Often caused by loose connections or worn-out components. Regular checks and timely maintenance can prevent this.

- Freeze-Ups: This can happen if settings are too low. Adjust the cut-out control to ensure smooth operations.

- Compressor Failures: If the high-pressure cut-out isn’t set right, it can lead to compressor burnout. Always verify your settings.

Our experts at Unity Cooling Systems Inc. are always ready to lend a helping hand—or if you prefer, a helping wrench!

How a High Pressure Cut Out Transformation Boosted Efficiency for Local Restaurants 🌟

Y’all ever heard about Lucy’s Diner? Let me tell ya, this beloved spot in the heart of Houston was in a pickle! 🍔🥒 Sitting at a 20-25% energy loss due to their high pressure cut out being set too high, they were cashing out way more than what the register was ringing in.

So, we wanted to fix that. We rolled up our sleeves and got to work, adjusting their high pressure cut out to a typical setting of around 15 psig. Here’s how we broke it down:

1. Current Setting Assessment:

- Previous High Pressure Cut Out: 25 psig

- Optimal Setting: 15 psig

- Difference: 10 psig

2. Cost Calculation:

- Let’s say, running their refrigeration system costs about $1 per psig per hour.

- Annual Operating Hours: 8,760 (24/7)

- Savings at 10 psig decrease:

- Savings Per Hour = $10 (10 psig * $1)

- Annual Savings = $10 * 8,760 = $87,600

3. Efficiency Boost:

- With the new setting, Lucy’s Diner can expect a 20% increase in energy efficiency.

- Total energy cost previously: $400 a month translates to about $4,800 a year.

- New annual energy cost after adjustments: $3,840, so they’re saving $960 every year on energy bills!

By bringing it down to a safe high pressure cut-out control, not only did Lucy save big bucks, but they also reduced wear and tear on their recovery equipment. Ain’t that a win-win? 💰🙌

Just like the mighty Gulf Stream, a well-functioning refrigeration system keeps everything cool and fresh—from that famous sweet tea to succulent brisket. Think about how much your favorite local spot could save with a little adjustment. So whether you’re running an ice cream shop on the corner or managing a bustling convenience store, it’s time to rustle up some savings!

Importance of Regular Maintenance and Verification

Regular maintenance is your best friend—like a trusty sidekick you can always rely on. Ensuring that the high-pressure cut-out settings are verified and adjusted means you’re prepared for anything. EPA guidelines stress the importance of routine checks, and we couldn’t agree more.

A well-maintained system is like a well-tuned guitar—always ready to play its best notes. With proper care, your refrigeration systems will keep running smoothly, allowing you to focus on what you do best—running your business.

Final Thoughts:

To sum up, the high-pressure cut-out setting in your commercial refrigeration unit is not just a detail—it’s the heart of your operation. By understanding its importance and adhering to best practices, you ensure efficiency, safety, and compliance.

Remember these key takeaways:

- Regularly verify and adjust your settings.

- Stay informed on EPA regulations.

- Invest in quality equipment and maintenance.

For expert advice or assistance, reach out to us at Unity Cooling Systems Inc.. Our partnership with financing solutions like FLEXXBUY ensures your equipment purchases are hassle-free. Until next time, keep it cool, Houston!

FAQ: High Pressure Cut-Out and Recovery Equipment 🚀

What’s the Deal with Recovery Equipment?

Recovery equipment is essential when it comes to managing refrigerants efficiently. Whether you’re running a bustling eatery or a convenience store, having the right recovery tools can not only save you money but also keep your system operating smoothly. Just like a trusty cowboy and his lasso, recovery equipment helps wrangle that refrigerant back when it’s time to do maintenance!

What’s a Low Pressure Cut-Out Control on a Recovery Unit?

Now imagine you’ve got a low-pressure chiller working hard to keep your drinks ice-cold. The low pressure cut-out control plays a vital role—it’s like your trusty guard dog keeping an eye on pressures and ensuring everything runs as it should kicking in when things get a little too high-strung.

How Does Liquid Low-Pressure Chiller Valve Work?

Oh, this little guy is a game changer for your system! When the heat kicks up, the liquid low-pressure chiller valve helps regulate the flow of refrigerant, keeping everything balanced and cool. Think of it like a fan at a hot Houston barbecue—keeping the air flowing, so everyone can enjoy their ribs without breaking a sweat!

What’s the Pump Tube All About?

The pump tube is the unsung hero of refrigeration systems. It circulates refrigerant like a good ol’ Texas two-step, ensuring that everything dances together harmoniously. If it’s not operating well, well, that’s like trying to do the Texas Two-Step with two left feet—it just won’t work!

What’s the Evaporator Freeze?

An evaporator freeze happens when the temperature drops too low for the refrigerant in the evaporator coil. Picture this: the evaporator is like a chilly icehouse, but when it freezes up, it’s as if the icehouse suddenly turns into a frosty block of ice. We don’t want that! Keeping an eye on your system can prevent this from happening.

What’s the Deal with Evacuating Refrigerant from a Low-Pressure Chiller?

Evacuating refrigerant from a low-pressure chiller is akin to giving it a fresh start. It involves removing old refrigerant to prepare for maintenance or repairs, just like cleaning out your fridge before the big holiday feast.

How Do I Deal with Cut In and Cut Rupture Issues?

If you’re facing cut in and cut rupture issues, don’t sweat it. This typically means your system isn’t switching between high and low pressures smoothly. Think of it as a dance routine that needs a little practice to get right. Keep an eye on your gauges, and you’ll tackle it like a pro!

What’s That PSI and 5 PSIG Thing?

PSI stands for pounds per square inch, a measurement of pressure in your HVAC system. When you hear about 5 PSIG, it’s simply referring to the pressure level your system should maintain. Staying below or at this range keeps everything running as cool as a cucumber!

You see folks, understanding how these systems work isn’t just about the techie jargon—it’s a step towards making your operations smoother than a Texas road after a fresh repaving! If you’re itching to learn more, how about taking a quick quiz on these terms? You’ll be factory-floor ready in no time! 🎉

Let’s Connect! 🌟

Hey there, Houston friends! If you’re ready to save greenbacks just like Lucy did, let’s chat! 🤠 We know how important it is to keep your refrigeration systems in tip-top shape—like a well-oiled machine—so drop us a line, and we can help you find that perfect high pressure cut-out setting. Don’t let those pesky energy bills wear you down! You can contact us here or pick up the phone and call us at +1 (281) 818-5959. 📞

But wait, there’s more! Follow our journey on LinkedIn to stay updated with the latest tips and tricks, and check out our YouTube channel for some awesome videos that break it all down for you! Let’s team up, and together, we can keep your operations smoother than a cool breeze on a Texas night. 🌬️💚